Maintaining the safety and originality of products, especially food products, is a significant concern for any brand. We know that no one likes unhealthy foods that pose serious health risks. In such cases, food packaging boxes are the best choice as they provide protection from unwanted risks. If you have ever noticed, you might have seen some colored dots on this packaging. What is the meaning of these dots? Let’s get to know more about food packaging and the colored dots on it!

What Are Circles On The Food Packaging?

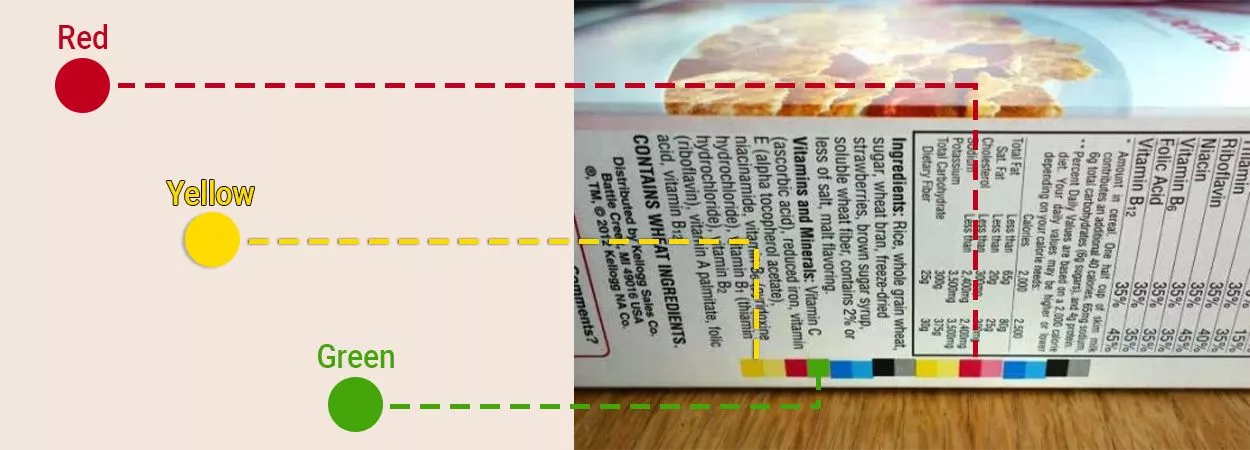

The circles on food packaging for printers are known as registration marks. The printers use these marks in the printing process to align various colors. The packaging design usually uses small crosses or circles for registration marks. This means that marks are references for printers to align every color for the accurate printing process.

It is a fact that every product comes with a distinctive color scheme, and the printer needs to verify it before printing the boxes. Therefore, a top-notch printer always picks the deviation easily from the available color palette. Therefore, you need to use the colored dots when printing the boxes for different types of products.

What Are The Colored Circles On Packaging?

The colored circles indicate several purposes, such as size, variety, quality, and shipping details. Therefore, it is important for food product owners and customers to have fundamental knowledge about the purposes of colored circles on the surface of packaging.

- Size Information: Various colored circles present different sizes of a product to enable customers to make well-informed purchasing decisions.

- Variety Details: The different colors indicate the different varieties of a product, allowing customers to easily know the product without removing the packaging to check the product.

- Quality Indication: These circles can show the quality of a product, which is a very important factor in maintaining the freshness of products over time.

- Shipment: Different circles can be used to specify instructions, shipping methods, and destinations.

The Main Purposes of Custom Food Packaging

Whether selling your edibles in physical stores or online, you need the right packaging solution. So, let’s first discuss the main purposes of custom food packaging!

Attract

The main purpose of packing your edibles perfectly is to attract the attention of potential customers. We know that your food products have to compete with many competitors. Therefore, it is very important to have an eye-catching packaging design (see: difference Between Packing and Packaging).

Display

Another purpose of the food box packaging is to demonstrate the benefits and purpose of your edibles. The packaging should make it clear what your product looks like and how customers can reap the health benefits.

Product notification

Your box should educate potential customers and provide all the information they need to feel confident in purchasing your edibles. This is where you should add nutritional information, the list of ingredients, and so on.

What About the Purposes of Personalized Food Packaging?

Personalized food packaging for e-commerce and online shops should be designed for other purposes. Let’s take a closer look at what that means.

Protection

The main purpose of the box when selling edibles online is to protect products throughout the shipping process. Your packaging box goes through multiple hands during delivery and is often dumped. For this reason, it needs to be strong, durable, and protective to protect your sensitive edibles from damage.

Promotional

Many brands tend to ignore the promotional potential of personalized food packaging. Well, the packaging you use to display your edibles in your online store plays an important role in the overall customer experience. This is sensible enough for your brand to pay attention to.

Colorful and printed food boxes bring more profit

Even for packing food products, you need colorful and printed food boxes to catch more eyes. Why? Because we love to see beautiful and colorful things.

This applies the same to customers when searching for their favorite meals online. Hence, it is no denying that colorful boxes will bring more profits to your food business!

What Are the Colored Dots On Food Packaging?

The colored dots on food packaging are part of a labeling system known as the “Nutrition Keys” or “Nutrition Facts Panel” which is used to provide information about the nutritional content of the food product. The colored dots represent the levels of key nutrients such as fat, sodium, and sugar in the food, allowing consumers to quickly identify how much of these nutrients are present in the product. The colors used on the dots correspond to the traffic light system, with green indicating a low amount of a nutrient, yellow indicating a moderate amount, and red indicating a high amount.

There is a lot of information we can see in modern customized food boxes. In addition to useful information such as nutritional information and ingredients, you might have seen colored dots on it. What are they?

If you don’t see colored dots on food packaging, don’t worry. Choosing to include this element is an option, not a rule. However, most large-format food products have colored dot variations in packaging. In fact, some companies might also cut color blocks during the packaging process.

Oh, and if you see colored dots, you will also know a scope crosshair-like icon is on the packaging. These “registration marks” (or “location marks”) are used to align all colors printed on a food package. This is a useful tool for printers but completely useless for consumers.

How to indicate Nutrition Facts Panel Amount in Food Product

The Nutrition Facts Panel on food packaging can be indicated by colors using the traffic light system. This involves assigning a green, yellow, or red color to different levels of nutrients present in the food product. For example:

Green:

indicates that a nutrient is present in low amounts (e.g., less than 5% of the recommended daily value)

Yellow:

indicates that a nutrient is present in moderate amounts (e.g., between 5% and 20% of the recommended daily value)

Red:

indicates that a nutrient is present in high amounts (e.g., greater than 20% of the recommended daily value)

The colors can be used on the Nutrition Facts Panel or on the front of the food package to help consumers quickly identify the nutritional value of the product. It’s important to note that the traffic light system is just one of many possible ways to indicate nutritional information with colors, and different countries or organizations may have their own systems or guidelines.

Different Color Dots by Countries or Organizations

While the traffic light system is a commonly used approach to using colors to indicate nutritional information, other systems and color-coding schemes can be used on food packaging. Here are a few examples:

High to Low:

This system uses different shades of a single color (e.g., red) to indicate the amount of a nutrient in a food product, with darker shades indicating higher levels and lighter shades indicating lower levels.

Black and White:

Some products use a simple black-and-white scheme, with the amount of each nutrient displayed in black if it is above a certain level (e.g., 5% of the recommended daily value) and in white if it is below that level.

Rainbow:

This system assigns a different color to each nutrient category (e.g., red for sugar, green for fat, blue for sodium), with the intensity of the color indicating the amount of the nutrient.

Guideline Daily Amounts (GDA):

This system uses colors to indicate the percentage of a person’s recommended daily intake of a nutrient contained in a serving of the food product. For example, a product might have a green circle to indicate that it provides less than 25% of a person’s daily intake of a nutrient, a yellow circle for 25-50%, and a red circle for more than 50%.

It’s important to note that there is currently no standard or mandatory color-coding scheme for nutritional information on food packaging, so the approach used may vary from product to product and from country to country.

Important Considerations When Printing Food Packaging

When it comes to printing food packaging, you need to be very careful. Not all printers are created equal. After all, we know that food products are sensitive. Thus, you need great care to maintain their essence and quality.

In short, choosing the best model for your business requires examining the production line and understanding certain factors.

To stay on the right track, ask yourself the following questions.

What Surface Material Are You Printing On?

The food packaging industry is a diverse field. Accordingly, some companies use different materials in their production lines.

The most common packaging materials we use for food products are such as:

- Aluminum

- Plastic

- Paper

- Glass

- Rigid material

- Cardboard material

As we can see, both permeable and non-permeable materials appear in this list. This difference can have a big impact on which printer meets your needs. Additionally, you need to consider whether the surface material is curved. For example, the case with bottled foods such as jams and pickles. These surfaces often require special printing that you can only do in certain printer models.

What Type of Ink Do You Need?

Food packaging printing requires careful attention to the inks you use. Finally, certain materials (such as cheap plastic) can be inconsistent and result in poor print quality. Luckily, there are some best solutions for your edibles’ needs.

Available options include:

Food grade ink

Manufactured under FDA Good Manufacturing Practices (GMP). This ink is guaranteed to be safe for human consumption. This makes it ideal for coding food contact packaging. Better yet, you can print directly onto the food itself.

Hypercook Ink

This ink is ideal for printing on pre-retort metal cans and plastic bags. A retort is a food sterilization technique in which the packaging of a container is sealed and then heated. What makes this ink unique is its ability to change color from green to blue in minutes.

Tips for Choosing the Right Color Combinations for Food Packaging

At the end of the day, whether you sell your food products online or offline, you definitely want to make high sales. Well, below are tips that might help you!

Show Off the Uniqueness of Your Food Products

The competition requires you to show off your food products in the best possible way. This is why you need to choose unique color combinations to design your packaging.

For instance, you can:

- Combine the white color packaging with gold foiling

- Choose a red color to make your food products more visible

Know What Your Competitors Are Doing

Speaking of competition, you also need to know about your online and offline brand competitors. Yes, you need to know what your competitors and their food boxes look like.

However, this does not mean that your food packaging has to match your competitor’s packaging. Be creative and do something different when printing your packaging. At the same time, make sure it captures the customers’ attention and interest.

Focus On Display Value

Your food packaging says a lot about your food product, including its value. When a customer considers a purchase, it means the quality of the packaging represents the quality of the product.

Prioritize Product Protection

As you know, protection is paramount when selling food products. For this reason, choosing the right ink, such as food-grade ink when coloring and printing your food packaging is necessary.

Create an Unforgettable Unboxing Experience

Customers these days crave an exciting unboxing experience. Of course, you need to deliver it to win their hearts. You can do this by printing your brand logo, colors, and fonts with special ink for food packaging.

Go Green

Customers want to be eco-friendly bakeries boxes too. Thus, your food packaging should do the same. Not only should the packaging be recyclable and sustainable. Instead, you can do your part to protect the environment by choosing eco-friendly and food-grade ink.

Wrapping Up

Without any doubt, maintaining food products’ safety and originality should be your major concern. This applies more intensely when it comes to printing your food packaging. So, hopefully, now you get clear ideas about food packaging and the colored dots on food packaging. To start designing and printing your packaging innovatively, you can work with The Custom Bakery Boxes!

FAQs.

Q. What are the main Purposes of custom food packaging?

- Attract

- Display

- Product notification

Q. What are the important considerations when printing food packaging?

- The surface material

- The type of ink

Q. What are the colored dots on food packaging?

This grid of batches is called “printer color blocks” or “process control batches.” Each of them indicates the colors used to create the packaging design.

Q. How to choose the right color combinations for food packaging?

- Show off the uniqueness of your food products

- Know what your Competitors are doing

- Focus on Display value

- Prioritize product protection

- Create an unforgettable unboxing experience

- Go green