It is not a secret that packaging is the one that protects your product. Additionally, it plays an important role in attracting customers. This is why you need to pay attention to it. To enhance the perceptible experience through your packaging, various options are available.

Yet, the two most popular options in the packaging industry are soft-touch coating and soft-touch lamination. Both techniques offer a luxurious feel for your packaging. However, they differ in terms of application, durability, and cost.

So, which one should you choose?

Well then, let’s explore the differences between the two techniques and their benefits!

What Is Soft Touch Coating?

Soft touch coating involves the application of a specific coating to packaging materials. By applying this coating, you can create a smooth and velvety texture for your packaging. This way, it will help you enhance the visual customer experience.

The Amazing Benefits of Applying Soft Touch Coating to Your Packaging

Applying soft touch coating to your packaging offers various amazing benefits. What are they?

It Provides a Luxurious Feel

This coating has a unique ability to engage the senses. Better yet, it provides a luxurious feel to the packaging. So, when customers touch your packaging, they will immediately experience a soft sensation from the surface. This can eventually leave a lasting impression. Moreover, it will help you create a positive brand association.

The Technique Improves the Visual Appeal of Your Packaging

Yes, this trendy coating can improve the visual appeal of your packaging. Additionally, the smooth texture it creates adds an element of elegance. Hence, it is perfect for making your bakery packaging look more premium.

It Comes with Scratch Resistance

Another great thing about this coating is that it offers great scratch resistance. This way, it protects your packaging from wear and tear. This will be beneficial if you transport your products over long distances. How?

This coating will act as a barrier for the packaging against scratches.

Soft Touch Coating Is Flexible

You can apply this technique to any packaging material. Whether you choose paperboard, cardboard, or certain types of plastic, this coating is ideal. In fact, this flexibility inspires many brands from different industries to prefer this technique.

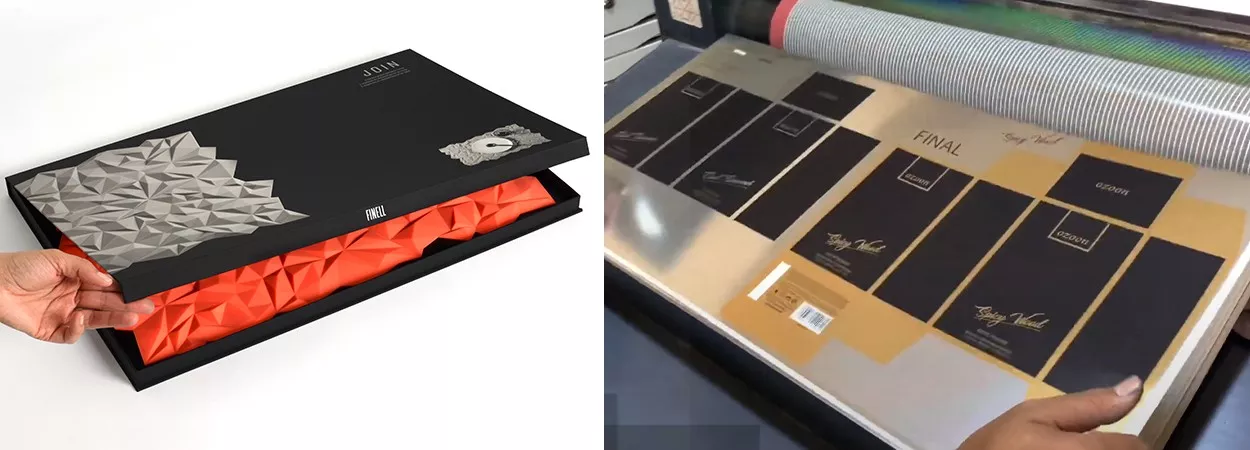

How Should You Apply This Coating?

- Apply it to your custom bakery boxes

The smooth and velvety feel of this technique can add an exceptional touch to your boxes. With this coating, you can complement your bakeries inside.

- It will be perfect for boxes from rigid

Applying soft coating or aqueous coating options to rigid boxes will enhance their look. Furthermore, this option will make your boxes feel smoother.

What Is Soft Touch Lamination?

Soft touch lamination is the application of a thin layer of plastic film to the packaging material. This film comes with a texture that provides a velvety feel to the surface. Additionally, it uses heat to add pressure to stick the film to the packaging material. As a result, this lamination helps you create durable and visually appealing packaging.

The Wonderful Benefits of Applying Soft Touch Lamination to Your Packaging

Of course, applying soft touch lamination to your packaging also offers some wonderful benefits.

Have a look at the most promising benefits below!

It Confirms Durability

Soft touch laminate offers better durability. How?

The plastic film provides an extra layer of protection. Hence, making your packaging more resistant. Thus, it will protect your product inside from scratches, moisture, and general wear. This durability will better protect your products in harsh shipping.

The Technique Optimizes Packaging Protection

The plastic film in lamination technique will act as a strong barrier. This means that it will secure your packaging from external elements. Even better, it optimizes protection from any potential damage during transportation. In the end, it helps to preserve the quality of your packaging. Ultimately, with durable packaging, you can ensure that your product arrives in the best condition.

It Delivers a Premium Appearance

When you apply this lamination to your packaging, it will deliver a premium look. Additionally, its velvety texture will add a touch of elegance. Well, this premium appearance will elevate your product’s value. Most importantly, it will make it more appealing to customers.

It Facilitates Branding Opportunities

This innovative lamination allows for other customization options, such as spot UV or foiling. By combining these options, you can create an eye-catching packaging design.

How to Ideally Apply This Lamination?

- Make your custom cake boxes look captivating with it

The laminated surface of your boxes not only will add durability. More than that, it will create a captivating look and feel. This way, your boxes will be an ideal choice for gifting occasions.

- It improves the overall luxury of your product

We all know that the unboxing experience is important. Well, the lamination technique will create a soft texture for your box. So, when customers touch the box, it creates a sensory experience for them. At this point, we can see how this technique will improve the luxury of your product.

Soft Touch Coating vs. Soft Touch Lamination – Which One is Better?

Of course, it can be tricky when deciding which option is better between the two. After all, both techniques offer unique benefits. Thus, to decide properly, you must focus on your priorities. This simply means that you must consider the specific needs of your packaging project.

Below are some factors you must consider!

-

The visual experience you want to deliver

If creating a luxurious feel is your top priority, soft touch coating is ideal. This coating offers a direct experience that can instantly captivate customers.

-

Durability and protection

Soft touch lamination provides better durability with its extra layer of plastic film. This will be beneficial if your packaging undergoes rough shipping. In addition, if you need packaging that withstands environmental conditions, this lamination is for you.

-

Visual appeal and customization

Soft touch lamination creates a premium appearance. Plus, you can combine it with other customization options like spot UV or foiling. So, if branding and visual aesthetics are essential for you, this lamination will be the best.

-

Consider your budget

It is to be noted that soft touch coating can be more expensive. Thus, this coating might not be suitable if you need a large quantity of packaging.

On the other hand, soft-touch lamination might come with higher upfront costs. Yet, it can be more cost-effective for larger production runs.

-

Material compatibility

Soft touch paper is most suitable for lamination. Meanwhile, soft touch coating is ideal for other materials. For instance, you can go with cardboard or plastic. Simply put, you should consider the compatibility of your materials with each technique.

To make things easier, you can always consult with packaging experts such as The Custom Bakery Boxes. They will provide further guidance according to your unique requirements.

In Summary

Indeed, both soft-touch coating and soft-touch lamination offer wonderful benefits. These innovative techniques work well to enhance the perceptible experience of your packaging. For instance, soft touch coating provides a luxurious feel. Plus, the technique comes with options for customization. However, it might have limitations in terms of durability and cost.

On the other hand, soft touch lamination offers better durability, protection, and branding opportunities. Yet, it might have limitations in material compatibility and thickness. Ultimately, the choice depends on your needs and other factors. So, make sure to choose the one that meets your needs and expectations!