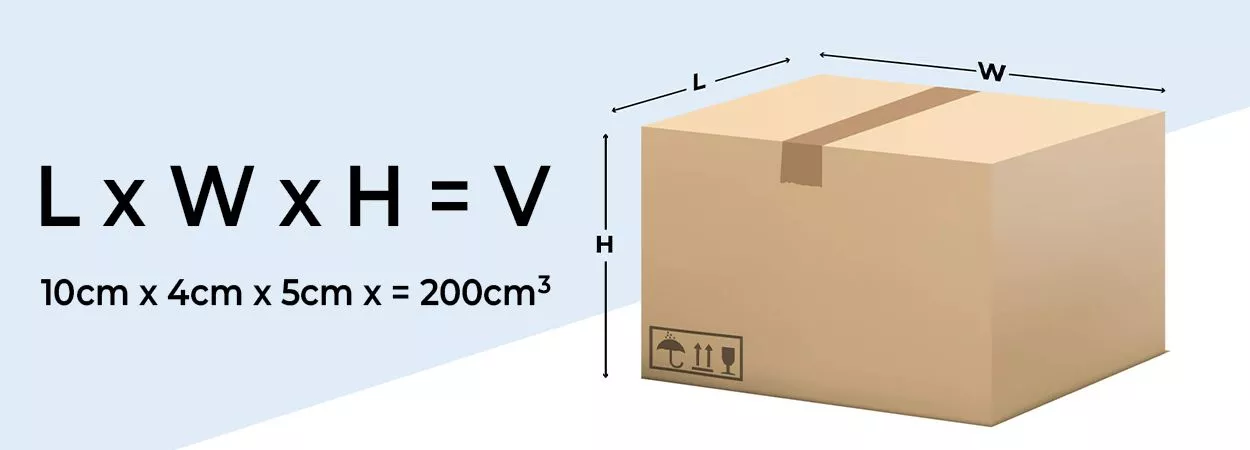

If you run a business that needs to ship products, you need the right box. Therefore, in order to properly pack and ship your products, you need to know how to measure the dimensions of your custom packaging. Of course, you don’t want to pack a small product in a huge box. On the other hand, you should not pack a big product in a small box. So, to help you out in this matter here is a complete guide to measure dimensions of a box in custom packaging. Let’s get started!

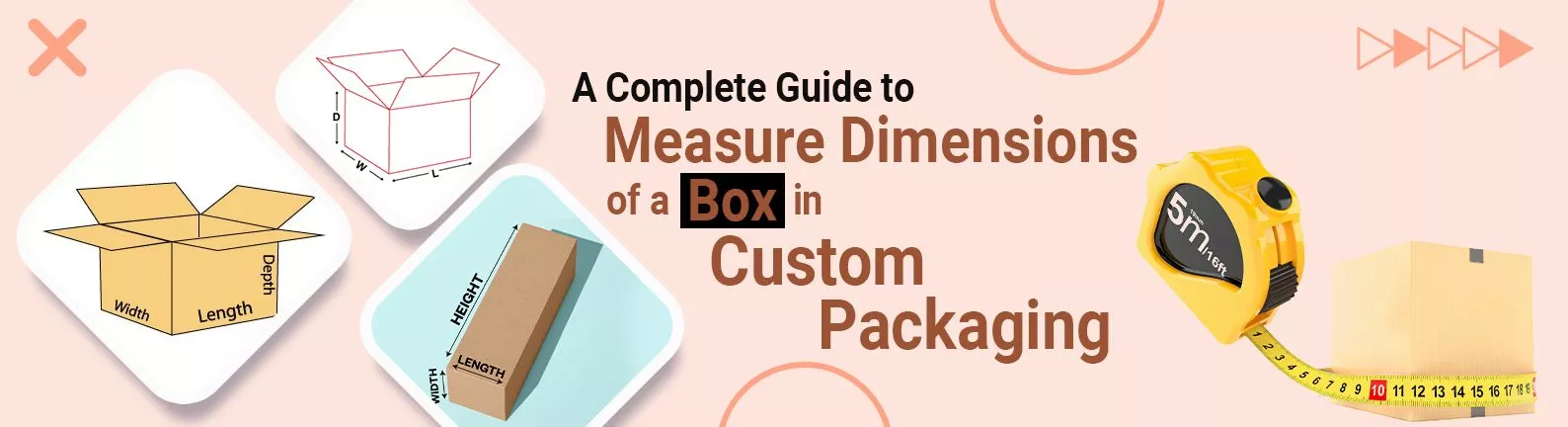

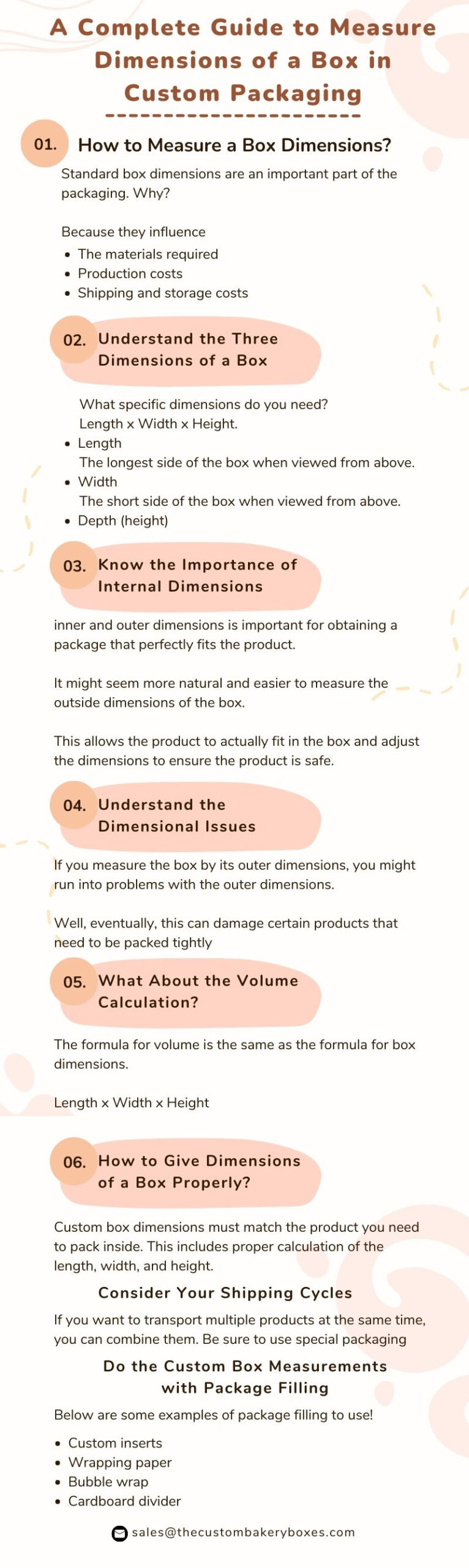

How to Measure a Box Dimensions?

Measuring the box seems quite easy.

However, in custom packaging, these dimensions are critical to product safety.

Standard box dimensions are an important part of the packaging. Why?

Because they influence:

- The materials required

- Production costs

- Shipping and storage costs

Think of it this way; minimal room to maneuver in the box means minimal room for damage and lower overall costs.

Hence, accurately measuring custom packaging projects is actually more complicated than it looks.

Well, here are some steps to measuring your box dimensions!

Understand the Three Dimensions of a Box

The first step in creating the perfect packaging is understanding how to measure your boxes accurately. This might seem like a rudimentary calculation. However, careful measurement requires some thought.

What specific dimensions do you need?

The three main dimensions by which a box is measured are length, width, and depth.

So, how to write dimensions of a box?

Length x Width x Height.

First, look at the top opening of the box and measure the following dimensions:

- Length

The longest side of the box when viewed from above.

- Width

The short side of the box when viewed from above.

- Depth (height)

Sides perpendicular to longitude and latitude.

For tall or reversed boxes, depth is the largest dimension, while length and width are smaller.

A square box should have equal sides, but the packaging makes this less likely. So, ensure to measure each dimension accurately so that the package matches the product.

For long boxes, the depth and width are much smaller than the length, as shown below.

The type of box you choose depends on the shape and size of your product. So what is girth measurement of a box?

Girth or width is essential when speaking about how to measure box size.

Regardless of the box type, the dimensions required for manufacturing vary depending on the length and width of the packaging box.

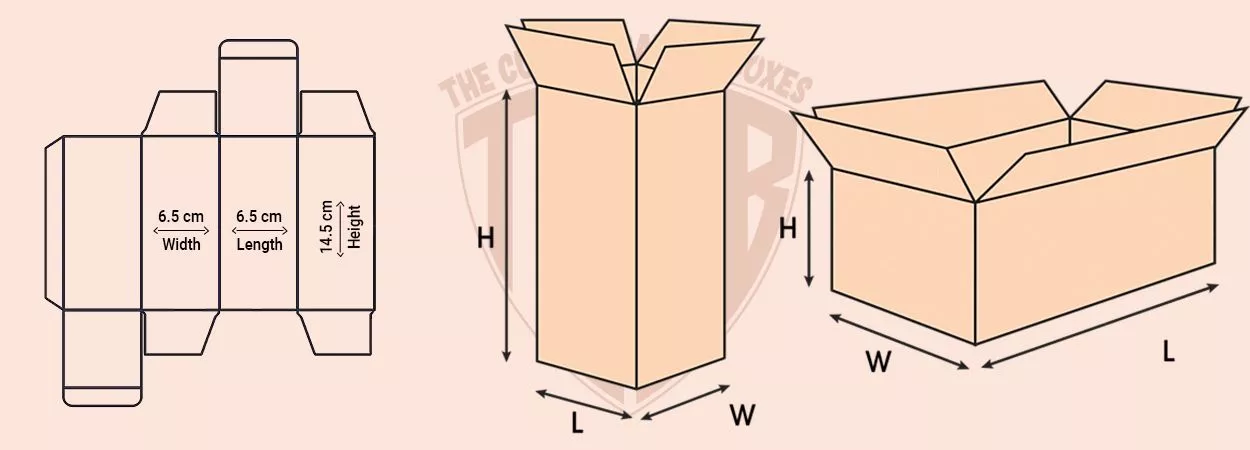

Know the Importance of Internal Dimensions

Industry standards for carton dimensions are based on internal dimensions.

Differentiating the inner and outer dimensions is important for obtaining a package that perfectly fits the product. Additionally, inside dimensions are more accurate for both manufacturers and products!

Most manufacturers are very specific about the size of both the inside and outside dimensions, and it’s no surprise. After all, no one wants their product damaged by wrong measurements.

It might seem more natural and easier to measure the outside dimensions of the box. However, the inside dimensions are actually important for custom packaging projects.

This allows the product to actually fit in the box and adjust the dimensions to ensure the product is safe. In the end, it helps in minimizing movement within the box. Thus, this effort ensures product safety during transportation and handling. Plus, allowing your business to deliver high-quality products consistently.

Understand the Dimensional Issues

If you measure the box by its outer dimensions, you might run into problems with the outer dimensions. Additionally, you might not focus on the thickness of the box. In the end, the package may not match exactly.

Well, eventually, this can damage certain products that need to be packed tightly.

Therefore, calculate girth of a package by internal dimensions is clear. This is especially important for corrugated boxes. Why?

Because corrugated boxes (see: Different Types of Packaging Material) have a wavy texture woven between the two boxes. This adds thickness to the material. More than that, it causes the dimensions of the outer lining of the box to vary by a few millimeters. Because of this, the inside dimensions provide a more accurate measurement. Hence, making it easier to determine the box size required to pack the product.

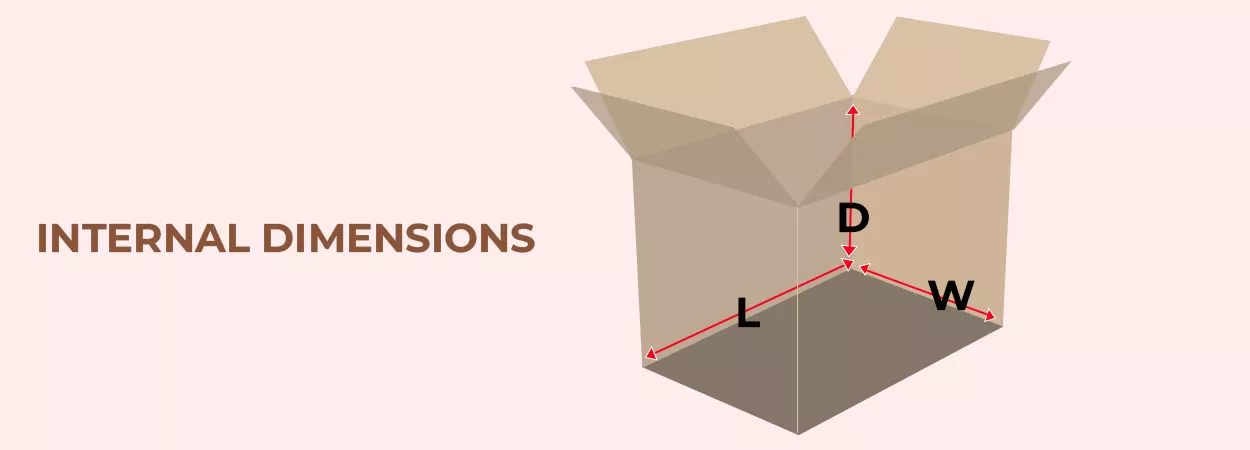

What About the Volume Calculation?

If you know how to correctly calculate the volume of a box, you can easily estimate the space it takes up. This is useful, for example, when: For example, determine how to measure shipping box amount to pack on a pallet. Plus, you can measure how much space each unit will occupy in your warehouse. The good news is that calculating volume is easy. All you need to do is multiply the order of dimensions of a box together. The formula for volume is the same as the formula for box dimensions.

Length x Width x Height.

But keep in mind that the final measurement will be a cube. That is, square inches, centimeters, or whatever unit you used to calculate the box dimensions.

How to Give Dimensions of a Box Properly?

Custom box dimensions must match the product you need to pack inside. Most importantly, it should be the right size actually to fit the product. To do this, we need to know the components of the product. This includes proper calculation of the length, width, and height.

However, even similar products cannot all fit in one box. This is why you need to find the perfect size and style for your special product.

For example, it makes no sense to pack a single cup into a giant box. Who wants to pay to ship empty air? Instead, the dimensions of the box should fit comfortably so that the item does not move inside.

So, let’s have a look at how to measure dimensions of a box for shipping below!

Consider Your Shipping Cycles

If you want to transport multiple products at the same time, you can combine them. Be sure to use special packaging. Otherwise, you should use interior lining to protect against collisions during transportation cycles.

For a mailer box size guide, you can do a drop test to make sure it is protected. Additionally, you must do an initial test using the dimensions of your custom packaging. This helps ensure that the package can withstand shipping influences.

Do the Custom Box Measurements with Package Filling

What goes into your product package really matters. In this context, we are not only talking about the products you deliver.

Void or package filling is a key component of custom box measurements. While stuffing can result in an improperly sized box, using package filling is essential to keep your products even more secure.

Below are some examples of package filling to use!

- Custom inserts

Custom inserts are especially popular with beauty brands. These inserts offer extra protection and add a classy touch to products. These inserts come in a variety of sizes, and you can customize their colors for a stunning final look.

- Wrapping paper

Wrapping paper is the most commonly used material to fill voids in packages. It greatly assists in the shipping process. It keeps your products safe and provides the highest level of protection during transportation. Additionally, you can add recyclable kraft paper inside to promote the concept of environmental protection.

- Bubble wrap

Bubble wrap is also a popular material for filling gaps in packages. However, bubble wrap might take up a lot of space. On the other hand, many brands use it to deflect the effects of damage.

- Cardboard divider

A cardboard divider is a quality packaging material that fills in the gaps inside the box. This divider will also add elegance and uniqueness to your displays. This material does not affect the overall size and dimensions of the box. Instead, you can add it to enhance their presentation and give your product a touch of luxury.

You can choose any of the above package filling materials according to your business needs. Still, the main goal is to use the best possible materials to improve the user experience. In the end, it should also make your custom packaging look more attractive.

In Summary

Determining the box dimensions you need can be daunting, especially if you are new to this matter. Hopefully, you get more knowledge after reading our complete guide to measure dimensions of box in custom packaging here. If you find any difficulties, you must consult an experienced packaging professional such as The Custom Bakery Boxes.

FAQs

Q. How to write dimensions of a box?

Length x Width x Height.

Q. How to give dimensions of a box properly?

Know the components of the product, including proper calculation of length, width, and height.

Q. How to measure dimensions of a box for shipping

Consider shipping cycles

Custom box measurements with package filling

Q. What are examples of package filling?

- Custom inserts

- Wrapping paper

- Bubble wrap

- Cardboard divider